Why does my chocolate have white spots?

You open your favorite chocolate bar and, surprise! White spots cover its surface like a mysterious veil. Don’t panic—your chocolate isn’t moldy. These white marks are actually a very common phenomenon with a simple scientific explanation. And guess what? Your chocolate is still perfectly edible.

The Two Types of White Spots on Chocolate

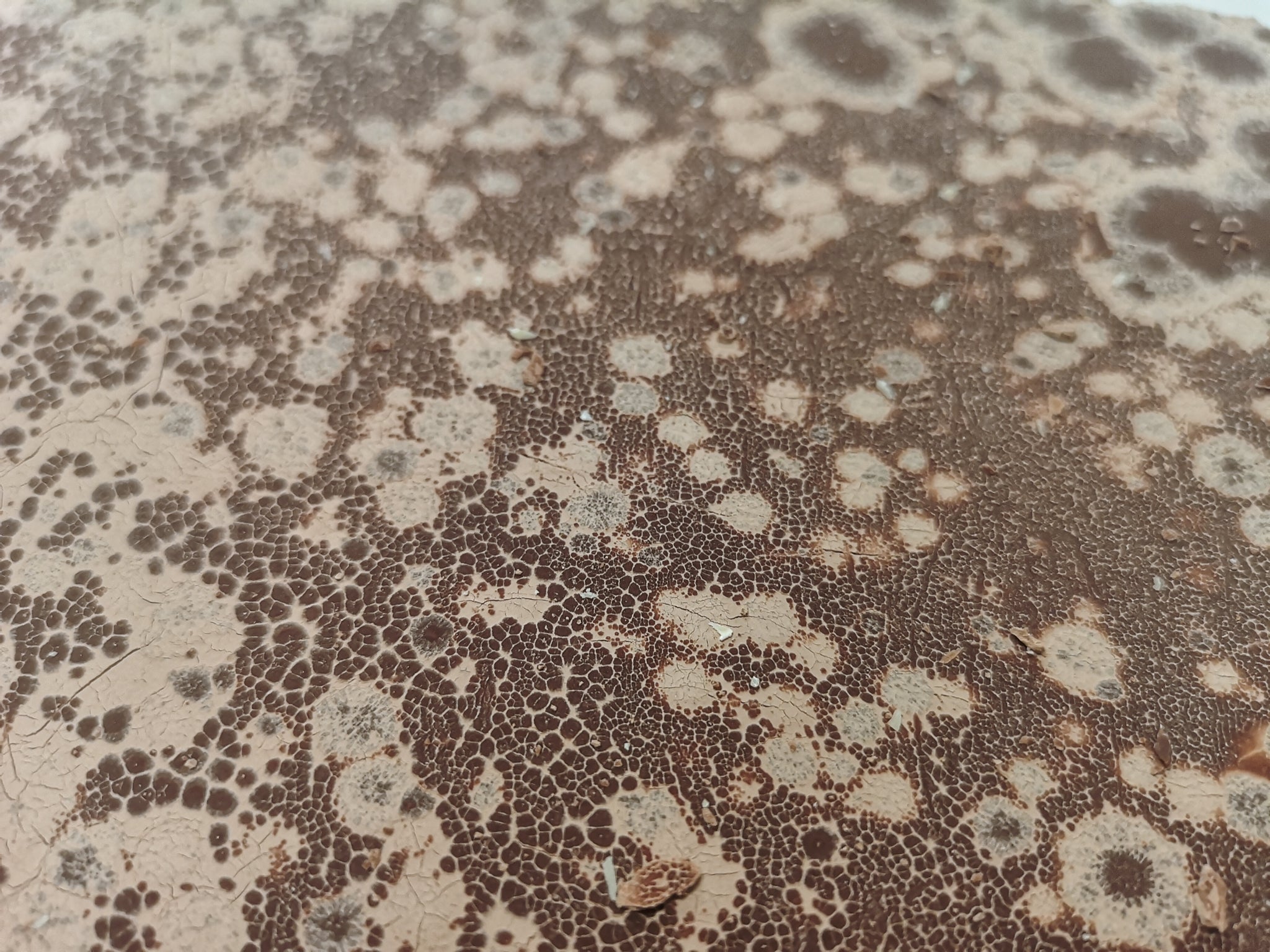

Fat Bloom

This is the most common type. It occurs when cocoa butter partially melts and then re-solidifies on the surface. When chocolate is properly tempered, all its components (sugar, fibers, cocoa butter, etc.) form a homogeneous structure. When it’s not tempered, this mixture becomes uneven, and the cocoa butter rises to the surface, creating those famous white spots when it solidifies again. It’s just like oil separating in a vinaigrette (but in solid form)!

Sugar Bloom

Less common, this type of bloom happens when moisture causes sugar to migrate to the surface of the chocolate. The visual result is similar, but the cause is different. The chocolate absorbs water from the air, dissolves some sugar, and when the water evaporates, it leaves behind white sugar crystals. This can happen when chocolate gets very cold, for example, after being in the freezer, and condensation forms on its surface.

Why Does Your Chocolate Develop White Spots?

Poor Tempering

Tempering is a delicate technique that involves heating and cooling chocolate to precise temperatures to properly structure the cocoa butter crystals. If this step isn’t done accurately, the crystals don’t form correctly. The result? Poorly tempered chocolate and the appearance of those pesky white spots that compromise its texture and appearance.

Improper Storage Conditions

Heat and humidity are chocolate’s worst enemies. Temperature fluctuations partially melt the cocoa butter, which then rises to the surface. Humidity causes sugar to dissolve and then recrystallize.

Storing your chocolate in a hot place, near a radiator or in the sun, or in a humid environment like a basement—or worse, the shower (very bad idea, haha)—encourages the appearance of these white spots.

How to Use Chocolate with White Spots

If the Texture Doesn’t Bother You

You can absolutely eat it! The taste remains almost identical; it’s mainly the visual aspect and texture that change slightly. Some even think these white patterns look like flower fields or lunar craters. However, if your chocolate is very old, it might be stale and have lost some of its flavor.

For Perfectionists

If the appearance bothers you and you don’t want to re-temper your sad-looking chocolate, you can use it in your culinary creations. It’s perfect for:

- Chopping into pieces for cookies

- Making a comforting hot chocolate (my favorite solution!)

- Preparing a ganache or mousse

- Incorporating into any dessert recipe you like (seriously, go wild!)

Once melted and mixed, no one will notice the difference!

Preventing White Spots on Chocolate

Store your chocolate in a dry place with a stable temperature (ideally between 15°C and 18°C / 59°F and 64°F), away from direct light. Avoid the fridge, as it would create a thermal shock when you take the chocolate out.

Wrap it carefully in its original packaging or in an airtight container to protect it from humidity and odors.

Your Chocolate Is Still Delicious, Promise!

The white spots on your chocolate are just an aesthetic and textural flaw. Don’t worry—they don’t affect the quality or flavor of the chocolate, which remains perfectly safe and delicious to eat. Whether you choose to eat it as is or use it in cooking, don’t waste your chocolate! By the way, I’ve heard that every time someone wastes chocolate, a unicorn dies somewhere in Africa (I might need to fact-check this, but better safe than sorry).

Now that you know the secret behind these mysterious white marks, you can enjoy your chocolate with peace of mind!